NETA ATS-2017

Switchgear and Switchboard

Assemblies

A. Visual and Mechanical

Inspection:

- Compare equipment

nameplate data with drawings and

specifications.

- Inspect physical and

mechanical condition.

- Inspect anchorage,

alignment, grounding, and required

area clearances.

- Verify the unit is

clean and all shipping bracing,

loose parts, and documentation

shipped

inside cubicles have been removed.

- Verify that fuse and

circuit breaker sizes and types

correspond to drawings and

coordination

study as well as to the circuit

breaker’s address for

microprocessor-communication

packages.

- Verify that current and

voltage transformer ratios

correspond to drawings.

- Verify that wiring

connections are tight and that

wiring is secure to prevent damage

during

routine operation of moving parts.

- Inspect bolted

electrical connections for high

resistance using one or more of the

following

methods:

- Use of a

low-resistance ohmmeter.

- Verify tightness of

accessible bolted electrical

connections by calibrated

torque-wrench

method in accordance with

manufacturer’s published data or

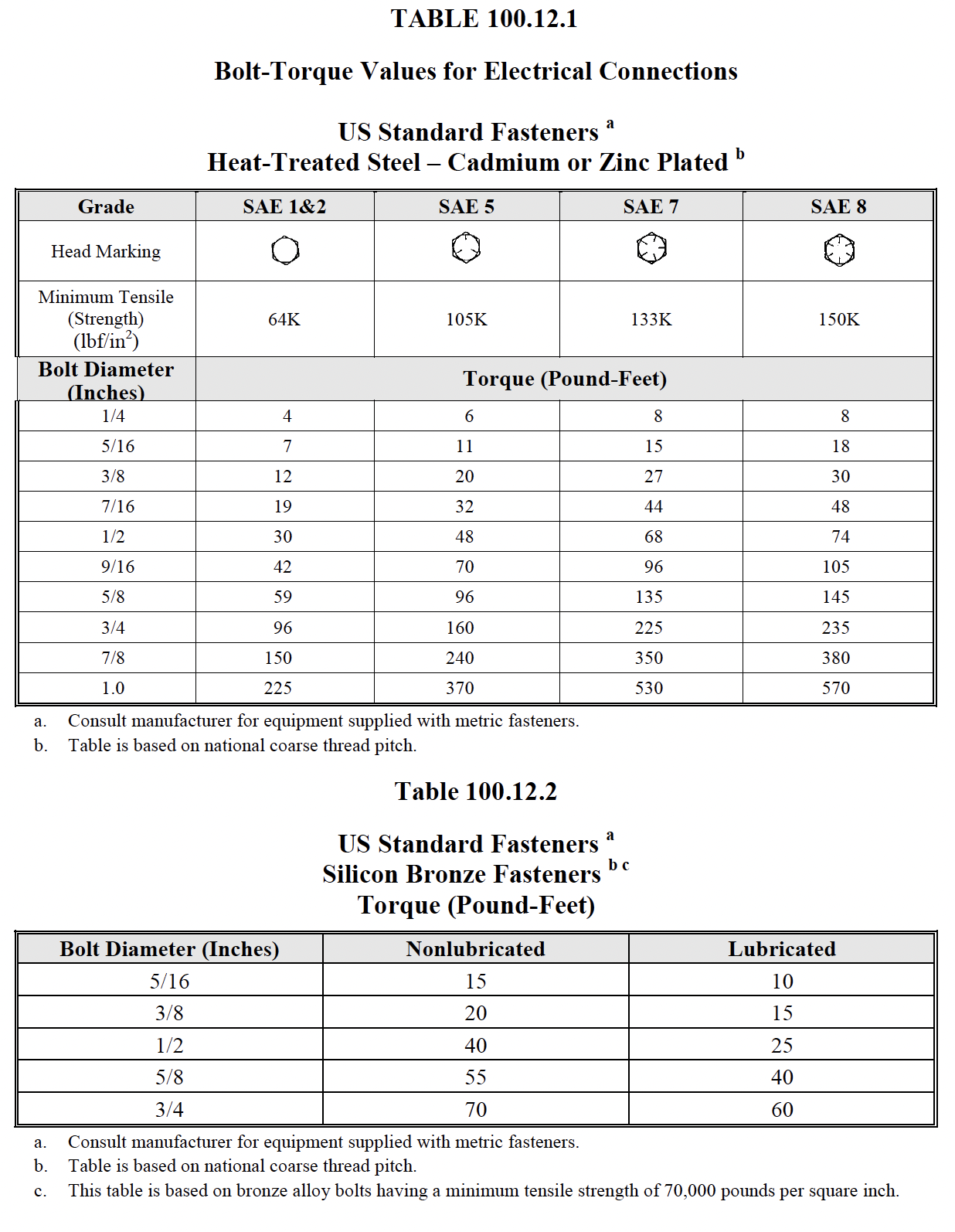

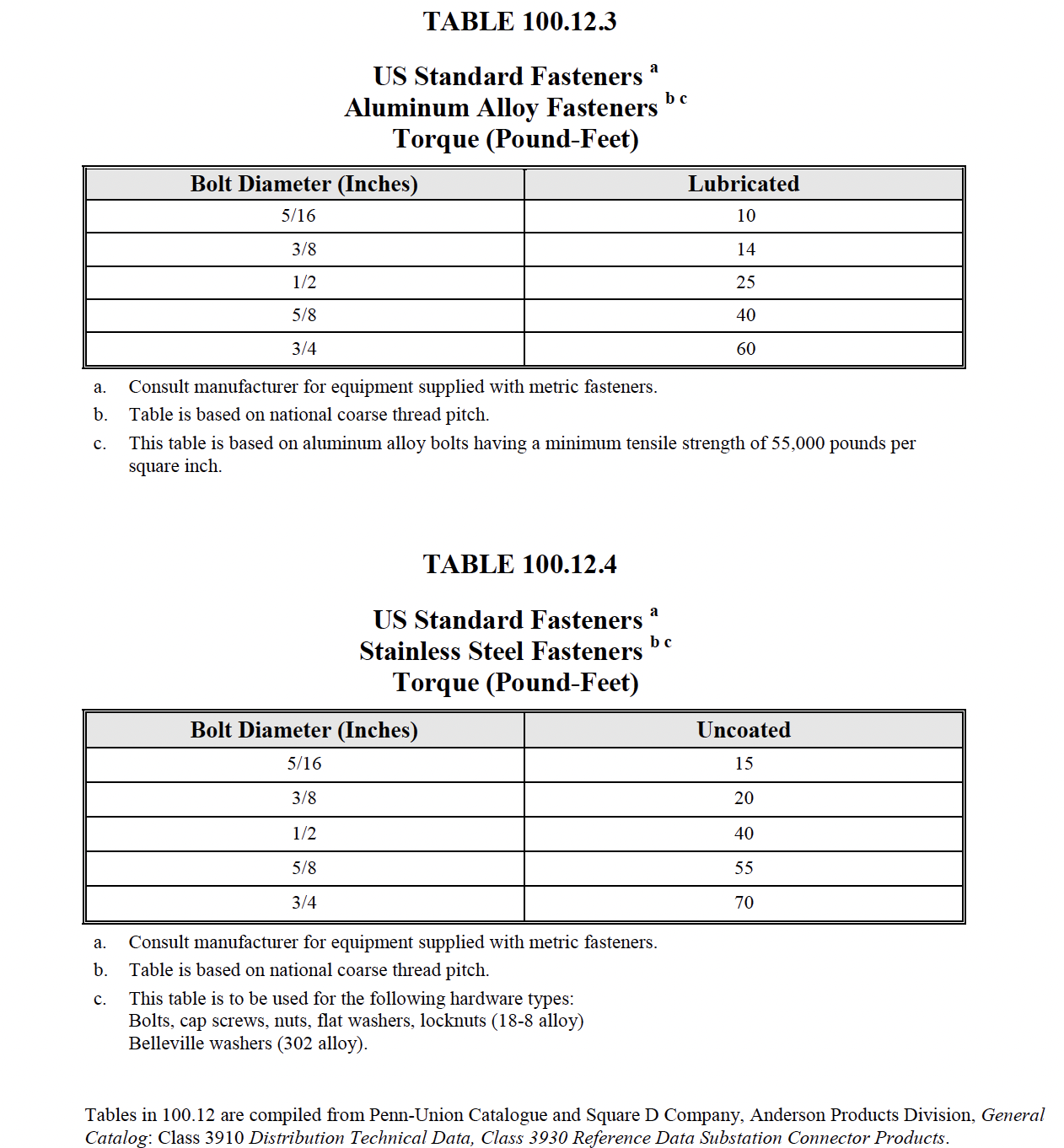

Table 100.12.

- Perform Perform

thermographic survey.

(optional).

- Verify operation and

sequencing of interlocking systems.

- Verify appropriate

lubrication on moving

current-carrying parts and on moving

and sliding

surfaces.

- Inspect insulators for

evidence of physical damage or

contaminated surfaces.

- Verify correct barrier

and shutter installation and

operation.

- Exercise all active

components.

- Inspect mechanical

indicating devices for correct

operation.

- Verify that filters are

in place and vents are clear.

- Perform visual and

mechanical inspection of instrument

transformers

- Perform visual and

mechanical inspection of surge

arresters

- Inspect control power

transformers.

- Inspect for

physical damage, cracked

insulation, broken leads,

tightness of

connections, defective wiring,

and overall general condition.

- Verify that primary

and secondary fuse or circuit

breaker ratings match drawings.

- Verify correct

functioning of drawout

disconnecting contacts,

grounding contacts, and

interlocks.

B. Electrical Tests:

-

Perform resistance measurements

through bolted connections with a

low-resistance ohmmeter,

-

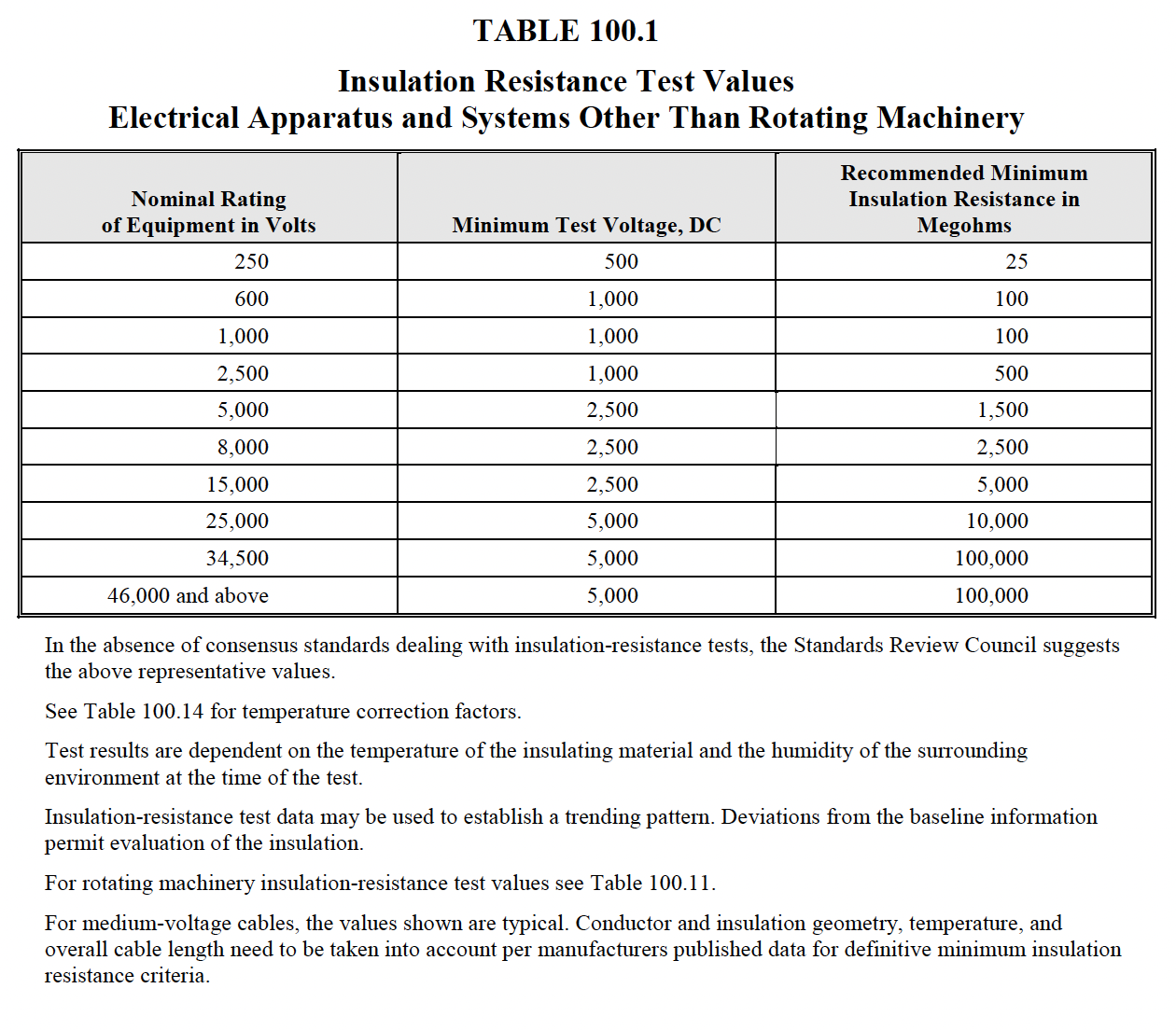

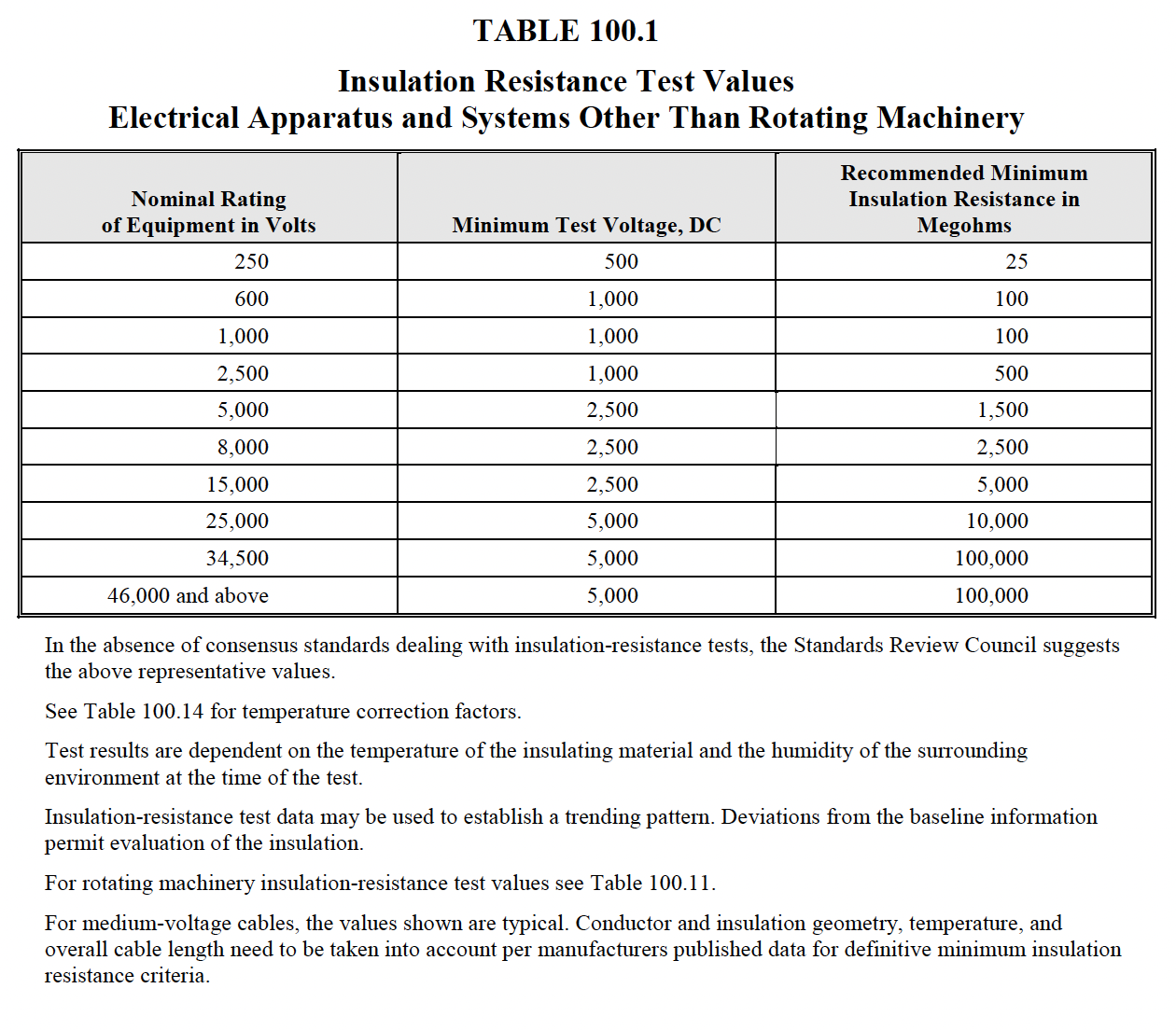

Perform insulation-resistance tests

on each bus section, phase-to-phase

and phase-to-ground,

for one minute in accordance with

Table 100.1.

-

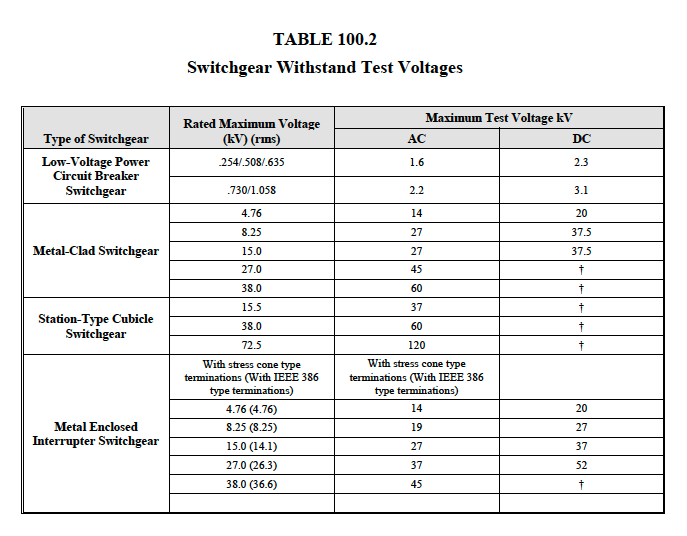

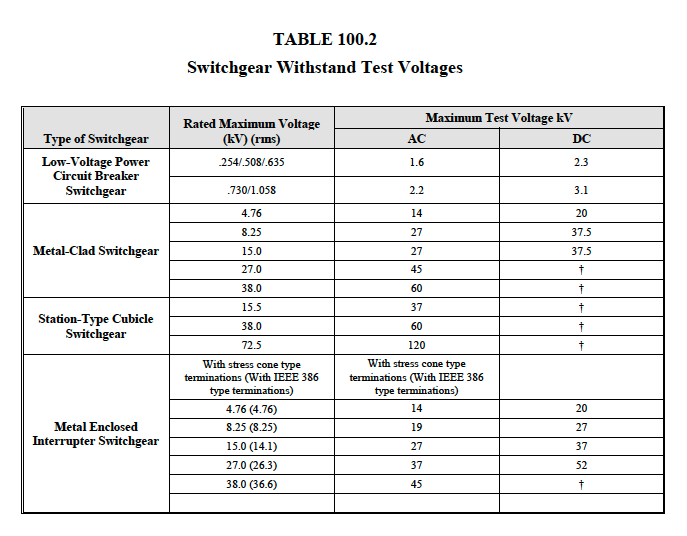

Perform a dielectric withstand

voltage test on each bus section,

each phase-to-ground with

phases not under test grounded, in

accordance with manufacturer’s

published data. If

manufacturer has no recommendation

for this test, it shall be in

accordance with Table 100.2.

The test voltage shall be applied

for one minute.

-

Perform insulation-resistance tests

on control wiring with respect to

ground. Applied

potential shall be 500 volts dc for

300-volt rated cable and 1000 volts

dc for 600-volt rated

cable. Test duration shall be one

minute. For units with solid-state

components or control

devices that can not tolerate the

applied voltage, follow the

manufacturer’s recommendation.

(optional)

-

Perform electrical tests on

instrument transformers

-

Perform ground-resistance tests

-

Test metering devices

-

Control Power Transformers

-

Perform insulation-resistance

tests. Perform measurements from

winding-to-winding

and each winding-to-ground. Test

voltages shall be in accordance

with Table 100.1

unless otherwise specified by

the manufacturer.

-

Perform a turns-ratio test on

all tap positions

-

Perform secondary wiring

integrity test. Disconnect

transformer at secondary

terminals and connect secondary

wiring to a rated secondary

voltage source. Verify

correct potential at all

devices.

-

Verify correct secondary voltage

by energizing the primary

winding with system

voltage. Measure secondary

voltage with the secondary

wiring disconnected.

-

Verify correct function of

control transfer relays located

in the switchgear with

multiple control power sources.

-

Voltage Transformers

-

Perform secondary wiring

integrity test. Verify correct

potential at all devices.

-

Verify secondary voltages by

energizing the primary winding

with system voltage.

-

Perform current-injection tests on

the entire current circuit in each

section of switchgear.

-

Perform current tests by

secondary injection with

magnitudes such that a minimum

current of 1.0 ampere flows in

the secondary circuit. Verify

correct magnitude of

current at each device in the

circuit.

-

Perform current tests by primary

injection with magnitudes such

that a minimum of

1.0 ampere flows in the

secondary circuit. Verify

correct magnitude of current at

each

device in the circuit.

(optional)

-

Perform system function tests in

accordance with ANSI/NETA ECS.

-

Verify operation of cubicle

switchgear/switchboard space

heaters.

-

Perform phasing checks on

double-ended or dual-source

switchgear to insure correct bus

phasing from each source.

-

Perform electrical tests of surge

arresters.

C. Test Values – Visual and

Mechanical

-

Compare bolted connection resistance

values to values of similar

connections. Investigate

values which deviate from those of

similar bolted connections by more

than 50 percent of the

lowest value.

-

Bolt-torque levels shall be in

accordance with manufacturer’s

published data. In the absence

of manufacturer’s published data,

use Table 100.12.

-

Results of the Perform thermographic

survey shall be in accordance with

Section 9. (optional)

D. Test Values –

Electrical

-

Compare bolted connection resistance

values to values of similar

connections. Investigate

values which deviate from those of

similar bolted connections by more

than 50 percent of the

lowest value.

-

Insulation-resistance values of bus

insulation shall be in accordance

with manufacturer’s

published data. In the absence of

manufacturer’s published data, use

Table 100.1. Values of

insulation resistance less than this

table or manufacturer’s

recommendations should be

investigated. Dielectric withstand

voltage tests shall not proceed

until insulation-resistance

levels are raised above minimum

values.

-

If no evidence of distress or

insulation failure is observed by

the end of the total time of

voltage application during the

dielectric withstand test, the test

specimen is considered to

have passed the test.

-

Minimum insulation-resistance values

of control wiring shall not be less

than two megohms.

-

Results of electrical tests on

instrument transformers shall be in

accordance with Section

7.10.

-

Results of ground-resistance tests

shall be in accordance with Section

7.13.

-

Accuracy of metering devices shall

be in accordance with Section 7.11.

-

Control Power Transformers

-

Insulation-resistance values of

control power transformers shall

be in accordance with

manufacturer’s published data.

In the absence of manufacturer’s

published data, use

Table 100.1. Values of

insulation resistance less than

this table or manufacturer’s

recommendations should be

investigated.

-

Turns-ratio test results shall

not deviate by more than

one-half percent from either the

adjacent coils or the calculated

ratio.

-

Secondary wiring shall be in

accordance with design drawings

and specifications.

-

Secondary voltage shall be in

accordance with design

specifications.

-

Control transfer relays shall

perform as designed.

-

Voltage transformers

-

Secondary wiring shall be in

accordance with design drawings

and specifications.

-

Secondary voltage shall be in

accordance with design

specifications

-

Current-injection tests shall prove

current wiring is in accordance with

design specifications.

-

Results of system function tests

shall be in accordance with

ANSI/NETA ECS.

-

Heaters shall be operational.

-

Phasing checks shall prove the

switchgear or switchboard phasing is

correct and in

accordance with the system design.

-

Results of electrical tests on surge

arresters shall be in accordance

with Section 7.19.

NETA MTS-2019

7.1 Switchgear,

Switchboard, and Panelboard

A. Visual and Mechanical

Inspection:

-

Inspect physical, electrical, and

mechanical condition.

-

Inspect anchorage, alignment,

grounding, and required area

clearances.

-

Prior to cleaning the unit, perform

as-found tests, if required

-

Clean the unit.

-

Verify that fuse and/or circuit

breaker sizes and types correspond

to drawings and

coordination study as well as to the

circuit breaker address for

microprocessorcommunication

packages.

-

Verify that current and voltage

transformer ratios correspond to

drawings.

-

Verify that wiring connections are

tight and that wiring is secure to

prevent damage during

routine operation of moving parts.

-

Inspect bolted electrical

connections for high resistance

using one or more of the following

methods:

- Use of a

low-resistance ohmmeter.

- Verify tightness of

accessible bolted electrical

connections by calibrated

torque-wrench

method in accordance with

manufacturer’s published data or

Table 100.12.

- Perform Perform

thermographic survey.

(optional).

-

Confirm correct operation and

sequencing of electrical and

mechanical interlock systems.

-

Attempt closure on locked-open

devices. Attempt to open

locked-closed devices.

-

Make key exchange with all

devices included in the

interlock scheme as applicable.

-

Use appropriate lubrication on

moving current-carrying parts and on

moving and sliding

surfaces.

-

Inspect insulators for evidence of

physical damage or contaminated

surfaces.

-

Verify correct barrier and shutter

installation and operation.

-

Exercise all active components.

-

Inspect mechanical indicating

devices for correct operation.

-

Verify that filters are in place

and/or vents are clear.

-

Perform visual and mechanical

inspection of instrument

transformers

-

Perform visual and mechanical

inspection of surge arresters

-

Inspect control power transformers.

-

Inspect for physical damage,

cracked insulation, broken

leads, tightness of

connections, defective wiring,

and overall general condition.

-

Verify that primary and

secondary fuse ratings or

circuit breakers match drawings.

-

Verify correct functioning of

drawout disconnecting and

grounding contacts and

interlocks.

-

Perform as-left tests.

B. Electrical Tests:

-

Perform resistance measurements

through bolted electrical

connections with a lowresistance

ohmmeter

-

Perform insulation-resistance tests

for one minute on each bus section,

phase-to-phase and

phase-to-ground. Apply voltage in

accordance with manufacturer’s

published data. In the

absence of manufacturer’s published

data, use Table 100.1.

-

Perform a dielectric withstand

voltage test on each bus section,

each phase-to-ground with

phases not under test grounded, in

accordance with manufacturer’s

published data. within

the absence of manufacturer’s

published data, use Table 100.2. The

test voltage shall be

applied for one minute. Refer to

Section 7.1.3 before performing

test. (optional)

-

Perform insulation-resistance tests

on control wiring with respect to

ground. The applied

potential shall be 500 volts dc for

300-volt rated cable and 1000 volts

dc for 600-volt rated

cable. Test duration shall be one

minute. For units with solid-state

components or control

devices that cannot tolerate the

applied voltage, follow

manufacturer’s recommendation.

(optional)

-

Perform electrical tests on

instrument transformers in

accordance with Section 7.10.

-

Perform ground-resistance tests in

accordance with Section 7.13.

-

Test metering devices in accordance

with Section 7.11.

-

Control Power Transformers.

- Perform

insulation-resistance tests.

Perform measurements from

winding-to-winding

and each winding-to-ground. Test

voltages shall be in accordance

with

manufacturer’s published data.

In the absence of manufacturer’s

published data, use

Table 100.1.

-

Verify correct function of

control transfer relays located

in switchgear with multiple

power sources.

-

Verify operation of

switchgear/switchboard heaters and

their controller.

-

Perform electrical tests of surge

arresters.

-

Perform online partial-discharge

survey in accordance with Section

11. (optional)

-

Perform system function tests

C. Test Values – Visual and

Mechanical

-

Compare bolted connection resistance

values to values of similar

connections. Investigate

values which deviate from those of

similar bolted connections by more

than 50 percent of

the lowest value.

-

Bolt-torque levels should be in

accordance with manufacturer’s

published data. In the

absence of manufacturer’s published

data, use Table 100.12.

-

Results of the Perform thermographic

survey shall be in accordance with

Section 9. (optional)

D. Test Values –

Electrical

-

Compare bolted connection resistance

values to values of similar

connections. Investigate

values which deviate from those of

similar bolted connections by more

than 50 percent of

the lowest value.

-

Insulation-resistance values of bus

insulation should be in accordance

with manufacturer’s

published data. In the absence of

manufacturer’s published data, use

Table 100.1. Values of

insulation resistance less than this

table or manufacturer’s

recommendations should be

investigated. Dielectric withstand

voltage tests should not proceed

until

insulation-resistance levels are

raised above minimum values.

-

If no evidence of distress or

insulation failure is observed by

the end of the total time of

voltage application during the test,

the test dielectric withstand

voltage specimen is

considered to have passed the test.

-

Minimum insulation-resistance values

of control wiring should be

comparable to previously

obtained results but not less than

two megohms.

-

Results of electrical tests on

instrument transformers should be in

accordance with Section

7.10.

-

Results of ground resistance tests

should be in accordance with Section

7.13.

-

Accuracy of metering devices should

be in accordance with Section 7.11.

-

Control Power Transformers

-

-

-

Heaters should be operational.

-

Results of electrical tests on surge

arresters shall be in accordance

with Section 7.19.

-

Results of online partial-discharge

survey should be in accordance with

manufacturer’s

published data. In the absence of

manufacturer’s published data, refer

to Table 100.23.

-

Results of system function tests

shall be in accordance with Section

8.

|